Automatic Lubrication System for Conveyors

Configurable oiling and greasing systems designed to enhance daily operations

Industrial Conveyors

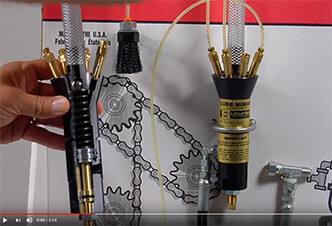

Oil and Grease Systems for Conveyors

Roller conveyors are vital for moving materials through processes, from point A to point B. Conveyors must be lubricated to reduce friction from constant movement, component wear, and ensure smooth, uninterrupted operation. By installing a lubrication system, you can extend the lifetime of conveyor parts and reduce maintenance to ensure it runs as efficiently as possible.

Increase the life of equipment by 4x and reduce maintenance by installing a Lubeminder lubrication system onto your equipment.

Critical points requiring lubrication

Roller conveyors must be lubricated at the most critical points to ensure they are running efficiently and reliably.

Roller Axle

Chains

Why LubeMinder?

Roller conveyors require reliable lubrication to meet shipping and assembly deadlines. With a reliable lubrication system, you can save time on maintenance, save money on expensive and time wasting repairs, and increase ROI. With our customizable automatic lubrication systems, we take out the guess work to ensure all critical points are being lubricated precisely and regularly with the perfect amount of lubricant. When designing your unique system, we keep in mind the ideal maintenance schedule, machine lubricant requirements, and operating conditions.

A LubeMinder lubrication system:

-

Improves lubricant delivery to critical

points -

Prevents corrosion

-

Reduces friction

-

Extends component life

-

Reduces downtime

-

Can be customized to your systems needs