Automatic Lubrication Systems

Our lubrication systems automatically oil and grease machinery - reducing the overall time spent maintaining tools and increasing the life of equipment. With the help of lubrication technologies, the chains are continuously lubricated efficiently while warming up and in use.

Automatic Lubrication Systems

Our lubrication systems automatically oil and grease machinery - reducing the overall time spent maintaining tools and increasing the life of equipment. With the help of lubrication technologies, the chains are continuously lubricated efficiently while warming up and in use.

Dependable lubrication, made simple.

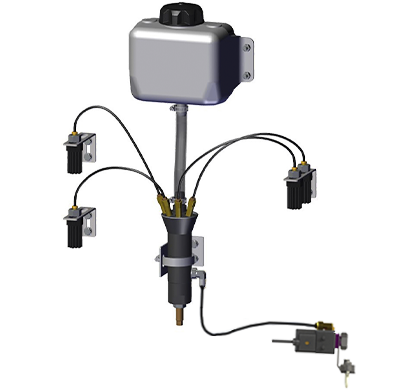

Equipment life improves, performance is maximized, and zerk fittings can be accessed centrally, all thanks to LubeMinder’s automatic lubrication systems for heavy equipment.

Automatic Oiling Systems

Auto lube systems for heavy equipment can improve operation and extend the life expectancy of the machine. This also means better value during trade-in.

The pump on the LubeMinder automatic oiling system provides reliable automatic lubrication, reducing the risk of metal-to-metal contact. Equipment parts stay adequately oiled and warm to facilitate better operation.

Automatic Grease Systems

Improve equipment reliability, reduce costly downtime and eliminate lubricant-related failures with an automatic greasing system.

Automatic grease systems lubricate points at the right time, with the right amount of grease, while in motion.

Custom Oil & Grease Systems

Made-to-order automatic lubrication systems for OEMs and critical applications. We design, manufacture and assemble kits in our U.S. headquarters.

Our Automatic Lubrication Systems are proudly Made in America. Experience the difference of partnering with an expert Tier 1 OEM supplier who has the highest American Made Manufacturing standards.

automatic lubrication for your industry

Our engineers have designed oil & grease pumps for multiple industries. By teaming up with OEMs, the sky is the limit in our capabilities:

Agriculture

Agriculture

Construction

Construction

Oil & Gas

Oil & Gas

Manufacturing

Manufacturing

Mining

Mining

Transportation

Transportation

Our Partners

AGCO: Automatic oilers and grease bank systems for 2300, 900, 5400, 5500, 6 Series, and 7 Series round balers.

CASE IH: Automatic oilers and grease bank systems for RB, RBX, and BR-A Series Round Balers. Oiling kits are available for 230, 240, all 5000, 6000, 7000, CR Series Combines.

John Deere: Automatic oilers and grease bank systems for 7, 8, 9, and Zero Series Round Balers. Oiling kits are available for S Series, STS, and Walker Combines.

Vermeer: Automatic oilers and grease bank systems for all 604N, 605N, and 504 model Round Balers.

QUESTIONS? START HERE