For OEMs, textile industry manufacturing plays an important role. Special textiles are used for equipment, machines, tools, hoses, and more. The purpose of textiles can be for the safety of the operator or the protection of a piece of equipment. The functions of textiles are vast, and offer the ability to improve operations, increase efficiency, save money, protect bystanders, and more. Industrial textiles are nothing new, but as technology advances, their uses are expanding quickly. From custom textile fabrics, to custom grommets, custom straps, and configurable turnkey solutions, many things can be made out of the textile of your choice.

In this article, we'll discuss what textiles are, their properties, their applications, and how you can embark on your custom textile journey:

- What are textiles?

- The properties of industrial textiles

- Our custom textile fabric options

- Custom textile industry manufacturing solutions

What are Textiles?

The definition of a textile is "a woven cloth; fabric or fiber." Textiles today go way beyond their original meaning. A textile can be a tightly woven piece of water-proof fabric, a plastic cover, or a loosely knitted blanket. Textiles play an important role in everyday life, but especially in manufacturing.

Industrial textiles can be extremely versatile or engineered and designed for a specific use. What determines the versatility of a textile is its properties and characteristics. The function of a fabric (the way it is designed) determines what it is used for.

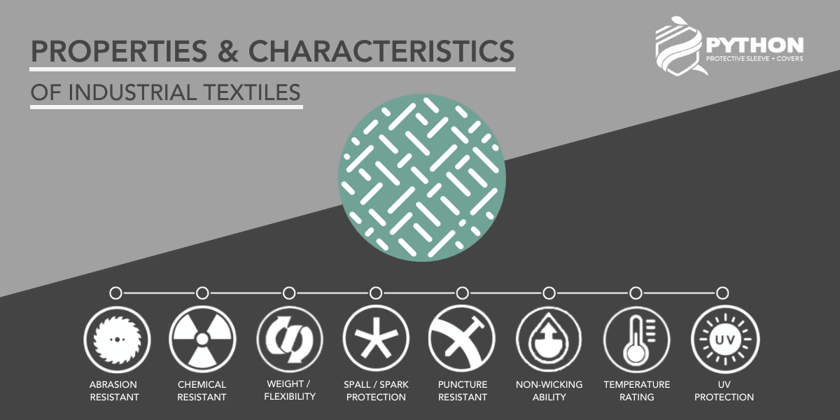

The Properties of Industrial Textiles

The properties of industrial textiles are vast. They're created to cover a lot of ground due to what solution they're engineered for. Their properties can range from UV protection to burst protection. It all depends on what the textile will be used for once it is sewn into the desired configuration. The graphic below highlights the most popular properties of textiles:

The number of characteristics is just the beginning - there are also a variety of industrial textiles to choose from for your custom part.

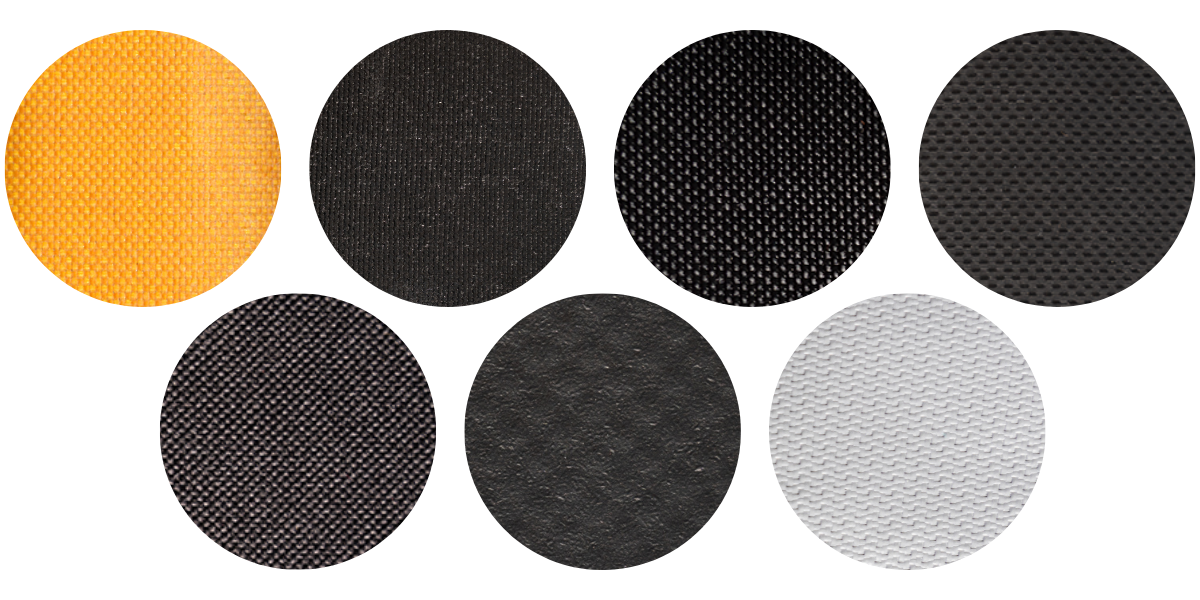

Python's Custom Textile Fabric

In the world of textiles, there are a variety of fabrics and materials used for an even larger variety of reasons. Each textile has a purpose, depending on the material they are made out of and how they are woven together. Industrial fabrics can cover a large range of functions and uses which makes them useful in many industries and applications. These are some of the most popular materials for industrial textiles:

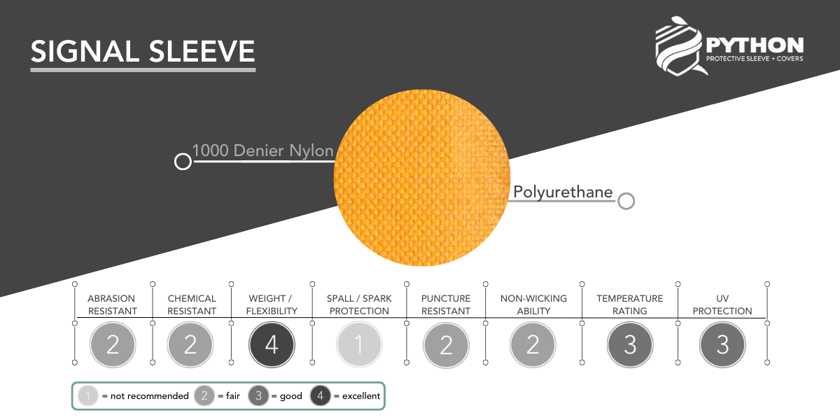

Signal Sleeve

The Signal Sleeve's core material is 1000 Denier Nylon and has a polyurethane coating. This material can handle temperatures up to 250oF and has extreme flexibility, so it can fit on almost anything. The signal is ideal for covering hoses, wires, and cords that may pose a danger to operator safety and can warn bystanders and pedestrians to stay clear of the area. This material is offered in a variety of colors and prints.

Most common uses:

- Bundling hoses, wires, and cords

- For awareness of liquid flow, danger, and chemicals

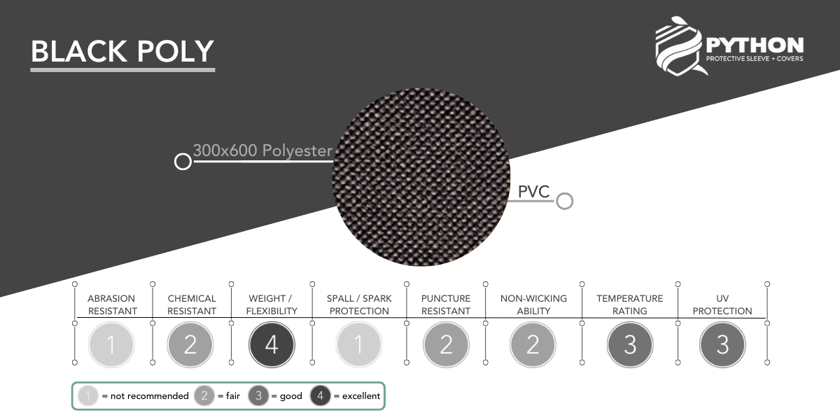

Black Poly

The Black Poly is made out of a polyester substrate and is coated in polyurethane. This material may not have the most robust properties as other materials do, but it's an amazing option when you need protection at an economical price.

Most common uses:

- Bundling hoses, cables, and wires on equipment and machines

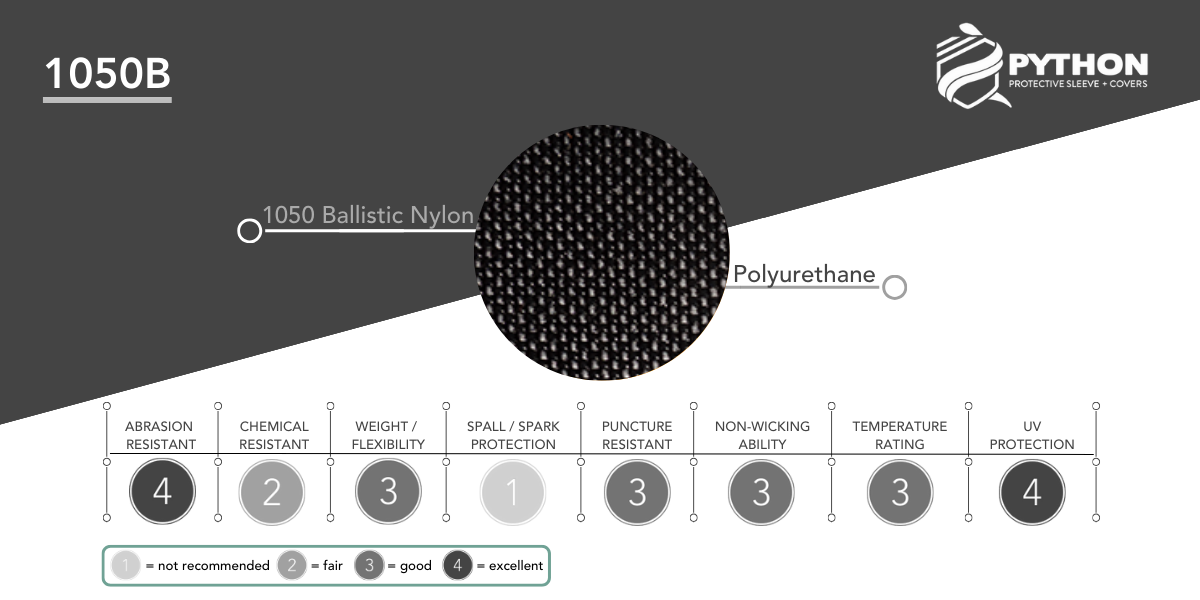

1050b

The 1050b is made out of ballistic nylon with a polyurethane coating. This material can handle temperatures up to 250oF and is chemical resistant. This material is ideal for general purpose applications, but it's equipped for a variety of industries.

Most common uses:

- Agriculture

- Construction

- Oil and Gas

- Forestry

- Mining

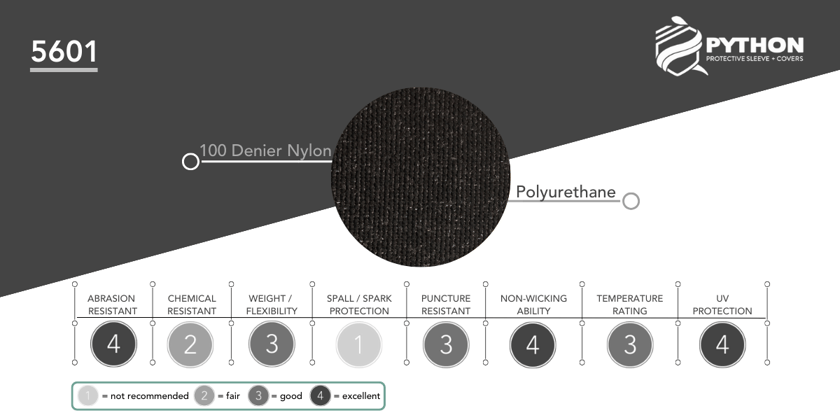

5601

The 5601 remains flexible no matter the temperature with a max of 225oF. Made out of nylon, it features a thick layer of polyurethane coating to reduce friction and is ideal for abrasion resistance and UV protection.

Most common uses:

- Mobile (spray foam)

- Industrial (machines)

- Agriculture

- Construction

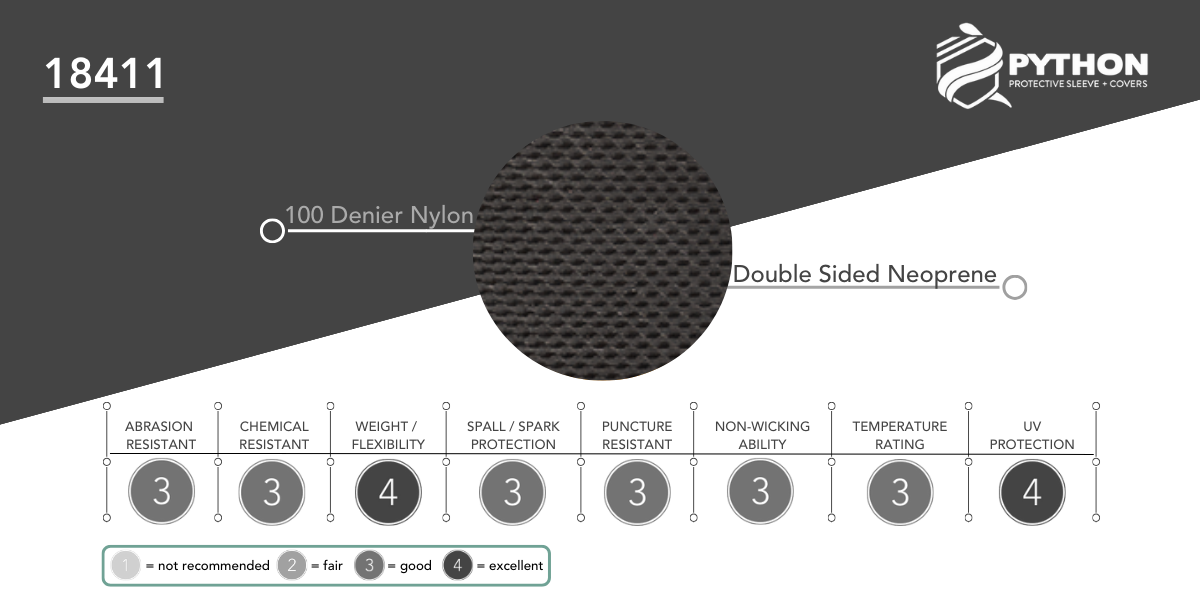

18411

The 18411 is made out of denier nylon and is coated with double-sided neoprene. This material can withstand the highest temperatures from 600oF to 1000oF intermittently. Its high temperature threshold allows this sleeve to last in high abrasion and high heat environments with sparks and spall.

Most common uses:

- Off-shore oil rigs

- Drill rigs

- Subsea Maintenance (saltwater/barnacle hose and wire protection)

- Welding

- Plasma Cutting

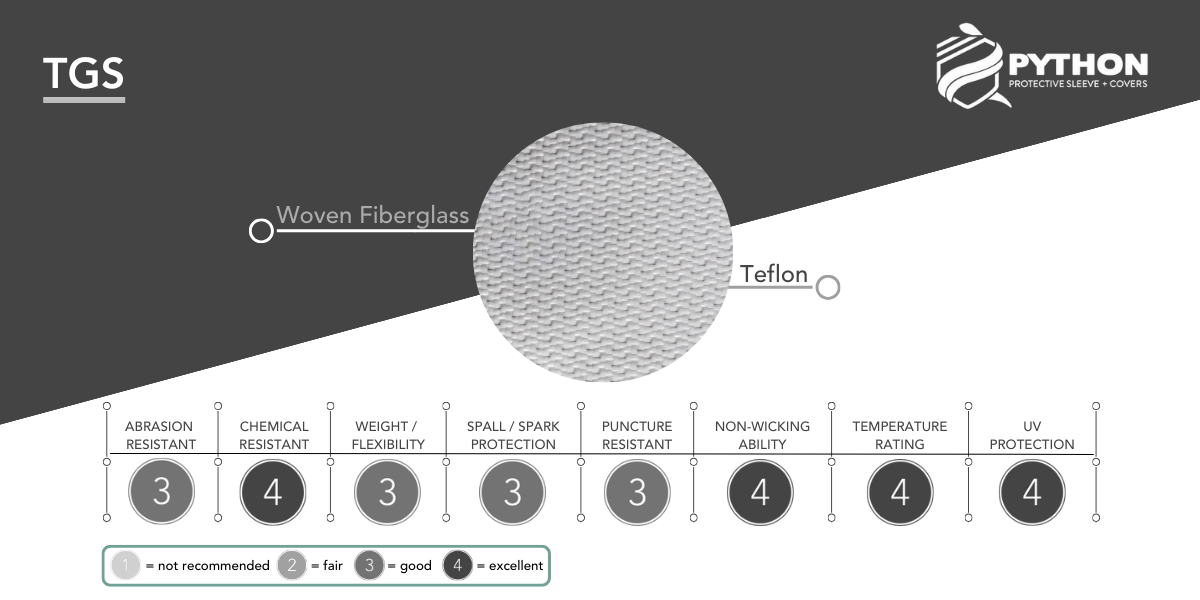

TGS

The TGS is made of tightly woven fiberglass and coated in Teflon. This material has a temperature threshold of 600oF. Additionally, it's resistant to flames, acidic chemicals, tar, asphalt, paint, and any other debris that ordinarily builds up on materials.

Most common uses:

- High-temperature applications

- Cables and wiring on sensors

- Harnesses on engines

- Welding

- Plasma Cutting

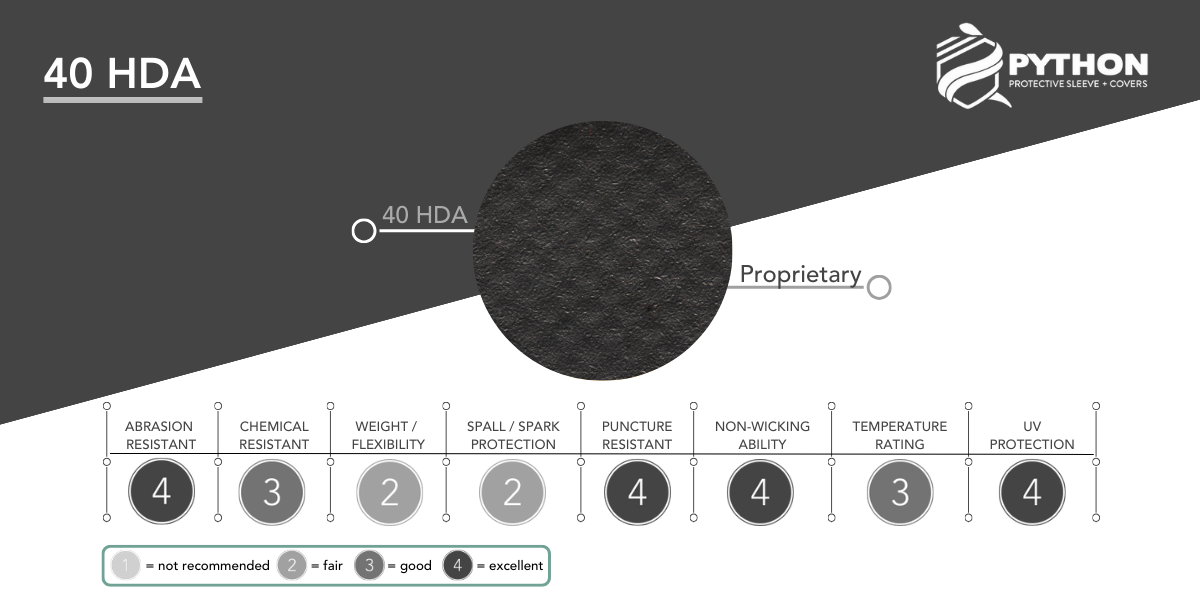

40HDA

Our 40HDA uses a proprietary coating designed to withstand temperatures up to 175oF. This material is heavy-duty, which makes it ideal for any high-abrasion outdoor applications. It can be dragged around in abrasive environments and still protect your equipment.

Most common uses:

- Mud pumping for well drilling

- Remote construction tools

- Heavy abrasion areas

- Pile Drivers

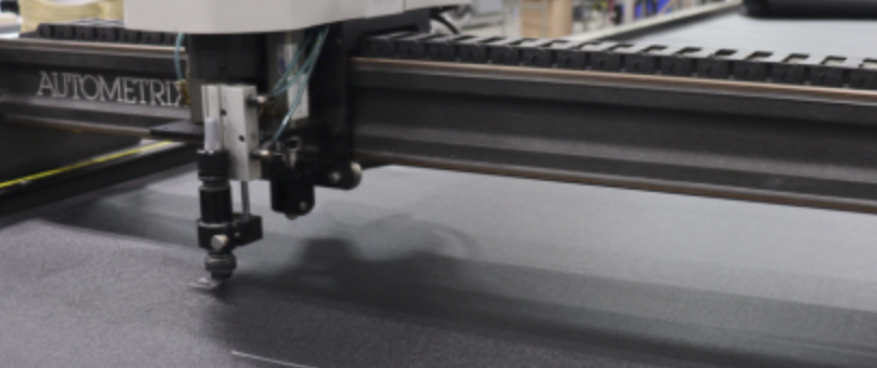

Custom textile Industry Manufacturing Solutions

Choosing the perfect fabric from various options is just the beginning of the custom textile journey. Here at Python, we want you to have the custom solution you need. We offer a variety of textiles and fabrics that can all be configured to your specifications and requirements - all while meeting compliance codes. We have a long history of creating custom solutions for OEMs, designed to transform the industry one custom solution at a time. Some of our solutions include:

- Custom grommets

- Custom textile fabric

- Custom straps

- Bundling straps

- and more!

If you need it, we can design it. We walk you through the process from ideation to creation, and keep you informed along the way for a no-surprise, communicative experience.

Let's chat so we can make a custom solution perfectly fit for you.