6 min read

Hook and Loop Straps: Optimal Solutions for Cable and Hose Organization

Python Covers Team

:

Aug 1, 2024 4:41:58 PM

You’ve likely managed a warehouse or workshop where cords and cables clutter the space, making it challenging to maintain order and safety.

Or maybe you’ve relied on rigid, permanent fasteners that, while effective, can complicate readjusting as the project requirements evolve.

When securing or organizing cables, you don’t have to choose between flexibility or reliability. Hook and loop straps offer a one-size-fits-all of adaptable, durable solutions for efficient management and accessibility.

In this article, we are discussing the benefits of a fire sleeve, the different types, and what they shield it from:

- Understanding Hook and Loop Straps: Cinch Straps and Their Uses

- Strap In: Exploring Various Cinch Options

- Hook and Loop Straps Across Industries

- Future Proof Your Protection Efforts

Understanding Hook and Loop Straps: Cinch Straps and Their Uses

Cinch straps are simple, yet effective tools used for securing and organizing various items. They consist of a long strip of material, usually nylon or polypropylene webbing, with a buckle or hook and loop fastener at one end, and a slot or hole at the other.

The most common materials used to make cinch straps are nylon and polypropylene webbing. These materials are chosen for their strength, durability, and resistance to abrasion and UV degradation. Additionally, cinch straps may also feature other components such as metal buckles or plastic hardware. These materials and components are carefully selected to ensure the straps can withstand heavy loads and endure any type of environment.

Basic Mechanics of Cinch Straps (How They Secure Items)

The basic mechanics of cinch straps hinge on their ability to tighten securely around objects through a simple yet effective fastening system.

When using a cinch strap, the user first wraps the strap around the item or group of items to be secured. The free end of the strap is then threaded through a buckle or passed through the slot/hole, and pulled tight.

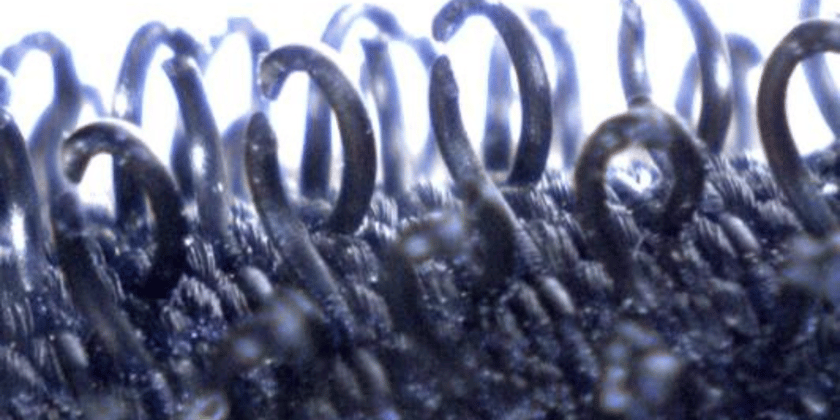

For straps with hook and loop fasteners, the hook side is pressed against the loop side to hold the strap in place. In the case of buckles, the design often includes a locking mechanism that prevents the strap from loosening once tension is applied. This locking action ensures that the secured items remain firmly in place, even under stress or movement. The ease of adjustment allows for quick and effective securing, making cinch straps a versatile solution for a wide range of applications.

Strap In: Exploring Various Cinch Options

There are several types of cinch straps, each designed for specific purposes. The most common types include:

- Custom Straps: These straps are designed to meet specific user requirements, offering flexibility in terms of length, width, and design. Custom straps can be tailored with particular colors, logos, or additional features like buckles or grommets to suit unique applications. They are ideal for situations where standard straps do not meet the necessary specifications, ensuring a perfect fit and optimal performance in specialized environments.

- Bundle Straps: These are specifically designed for bundling together multiple items, such as cables, hoses, or equipment. Bundle straps usually feature a wide surface area to distribute pressure evenly and reduce the risk of damage. They are commonly used in settings like data centers, workshops, and home organizations, providing a neat and secure way to manage and store items.

- Heavy Duty Cinch Straps: Built to withstand substantial loads and endure rugged conditions, heavy-duty straps are made from reinforced materials and may include extra stitching for enhanced strength. These straps are suitable for demanding applications such as securing large equipment, industrial machinery, or outdoor gear. Their robust construction ensures reliability and durability even under extreme stresses.

- Industrial Straps: These straps are designed for use in industrial settings where high strength and resistance to harsh environments are crucial. Made from materials like high-strength nylon and featuring corrosion-resistant hardware, industrial straps can handle heavy weights, chemicals, and extreme temperatures. They are commonly used in the manufacturing, construction, and transportation sectors.

- Hook and Loop Cinch Straps: Designed for managing and organizing cables, these straps feature a slim profile and easy-to-use hook and loop fastening system. They are perfect for keeping cords and wires tidy and accessible in home entertainment systems, office setups, and networking installations. Hook and loop cable straps can be quickly adjusted and reused, making them a practical solution for cable management needs.

| Type of Strap | Material | Common Uses | Key Features Compared to Hook and Loop |

|---|---|---|---|

Custom Straps |

Nylon, polyester, other synthetics |

Promotional products, equipment manufacturing |

Customizable size, color, and features like buckles or grommets; ideal for individualized applications |

Bundle Straps |

Durable nylon or polypropylene |

Data centers, workshops, home organization, telecommunications |

Wide surface area to distribute pressure evenly; reduces risk of damage |

Heavy Duty Straps |

Reinforced nylon or polyester, extra stitching |

Construction, transportation, industrial machinery, outdoor equipment |

Enhanced strength for substantial loads and rugged conditions |

Industrial Straps |

High-strength nylon, corrosion-resistant hardware |

Manufacturing, construction, transportation, chemical processing |

Resistant to heavy weights, chemicals, and extreme temperatures |

Hook and Loop Cinch Straps |

Hook: made of stiff plastic Loop: softer, looped-like fibers made from polyester or nylon |

Home entertainment, office setups, networking installations |

Slim profile, easy to adjust and reuse, ideal for organizing cables |

Hook and Loop Straps Across Industries

Cinch straps and hook and loop fasteners are widely used in various industries. Some common applications include:

- Construction: Builders, contractors, and other construction professionals use cinch straps to secure building materials, equipment, and tools. Hook and loop fastening systems are commonly used to organize cables, wires, hoses, and other items on job sites.

- Agriculture: Farmers use cinch straps for bundling crops or securing farm equipment. The versatility of hook and loop straps makes them ideal for managing irrigation lines and livestock fencing.

- Automotive: Car owners often use hook and loop straps to keep cargo or emergency equipment in place while traveling. In manufacturing facilities, hook and loop straps are used to secure wires, hoses, and other components during vehicle assembly.

- Recreation: Cinch straps are essential tools for outdoor enthusiasts. They help secure gear on backpacks, bikes, and camping equipment. Hook and loop fasteners are also commonly used to bundle items like sleeping bags or tents.

- Fashion: Hook and loop fabrics have become popular in the fashion industry as a trendy yet practical material for clothing and accessories. From custom cinch strap belts to unique handbags with hook and loop closures, the possibilities for incorporating these versatile fasteners into fashion designs are endless.

- Medical: In the medical field, hook and loop fasteners are used in various applications, such as securing bandages or attaching medical devices. They offer a secure yet adjustable solution for patients with sensitive skin who may have allergies to traditional adhesives.

- Electrical: Electricians and technicians use cinch straps and hook and loop fasteners to organize and secure cables, wires, and other electrical components. These fasteners provide a flexible and reusable solution for cable management, ensuring a tidy and efficient workspace. They are also useful for bundling and labeling different sections of wiring in both residential and commercial installations, making troubleshooting and maintenance easier.

- HVAC : Cinch straps and hook and loop fasteners are employed to secure duct-work, hoses, and insulation materials. These fasteners help maintain orderly installations and facilitate quick adjustments or repairs. Their durable nature ensures that components remain securely in place, even under the stress of fluctuating temperatures and airflow. HVAC professionals also use them to bundle excess tubing and keep work areas safe and organized.

Exploring the Pros and Cons of Hook and Loop Cinch Straps

- Versatility: Hook and loop straps come in various types and sizes, making them suitable for a wide range of applications. Whether you need to secure cables, bundle items together, or hold equipment in place, there's a hook and loop strap designed for that specific purpose.

- Reusability: Unlike other fastening solutions that may need to be cut or replaced after use, hook and loop straps can be easily released and reused. This makes them an environmentally friendly choice as they reduce waste and provide a reliable solution for multiple applications over time.

- Customizability: With the option to adjust the tension and length of the strap, hook and loop straps can be customized to suit specific needs. This flexibility allows for a precise fit, ensuring that the strap holds items securely without causing damage or being too loose.

- Durability: Made from sturdy materials, hook and loop straps are not easily damaged by frequent use or harsh conditions. They can withstand heavy loads, exposure to the elements, and regular wear and tear, making them a dependable option for both indoor and outdoor use.

- Cost-effective: Hook and loop straps are relatively inexpensive compared to other fastening solutions and have a longer lifespan, making them a cost-effective choice in the long run. Their durability and re-usability mean you won't need to frequently replace them, saving money over time while maintaining functionality.

Deciding if hook and loop cinch strap is your perfect fit

Selecting the appropriate fastening solution is crucial for ensuring the efficiency and safety of your projects. To determine if this cinch strap is right for you, consider:

1. Application Demands

Understand what are the specific needs for your project and if you will need to organize materials more than once to be transported. Hook and loop cinch straps excel in scenarios requiring frequent adjustments and reusability. They are ideal for organizing cables, securing lightweight items, and applications where ease of use is paramount.

2. Materials

While hook and loop cinch straps offer versatility and moderate strength, they may not be suitable for heavy-duty applications that demand extreme holding power. For such cases, consider using reinforced or industrial-grade straps instead. Identify any specific dimensions or features required for your application. Hook and loop cinch straps come in various sizes and can be customized with additional features such as padding or hooks. Ensure the strap you choose fits the exact needs of your project.

3. Environment Concerns

Hook and loop materials can degrade under extreme temperatures, UV exposure, or chemical contact. If the straps will be exposed to harsh conditions, ensure they are made from resistant materials or explore alternative fastening methods.

4. Plan for Adjustability

Hook and loop fasteners are reusable and suitable for applications where the strap must be frequently re-positioned or removed. If you require a long-term, permanent solution, a different type of cinch strap might be more appropriate.

5. Costs

Hook and loop cinch straps are generally cost-effective and offer a longer lifespan due to their reusability. If you need a reliable yet economical solution, these straps can provide excellent value for money.

hook and loop cinch straps: merging flexibility and efficiency

Redefining your approach to security and organization can seamlessly blend flexibility with efficiency, achieving both without compromise. Hook and loop straps offer a practical solution with their adjustable and reusable design, making them the right choice ranging from office organization to industrial settings.

For those who need a versatile and reliable fastening option, hook and loop cinch straps provide an ideal balance. They are easy to use and reposition, supporting a streamlined and effective management of materials with ease of transporting.

Wrap Up Your Worries: Secure Your Hook and Loop Straps

The most effective way to ensure that a particular cinch strap meets your project's specific needs is to engage with a specialized supplier. Our experts can tailor advice and product recommendations based on your project's requirements.