2 min read

Weld Armor Cable and Lead Wrap - New Product Winter 2025

Python Covers Team

:

Jan 10, 2025 2:53:07 PM

Python Sleeves & Covers Announces New Weld Cable Wrap for Winter 2025

In the demanding world of welding, where heat, abrasion, and harsh environments are a daily obstacle, protecting your valuable welding cable is paramount. Tangled wires, damaged insulation, and costly downtime due to cable damage can disrupt productivity, increase project costs, and compromise safety.

The Python Weld Armor Series introduces a line of weld cable wraps, meticulously crafted to safeguard your investment and enhance your welding operations. Experience unparalleled protection, enhanced organization, and increased efficiency with Python Weld Armor, the ultimate solution for all your welding cable needs.

VIDEO: 5 Cable Wraps for Welding Applications

This winter, Python Sleeves and Covers is broadening our product lineup with five innovative materials engineered for welding applications. The Weld Armor Series wraps are available for purchase through our Python sales team.

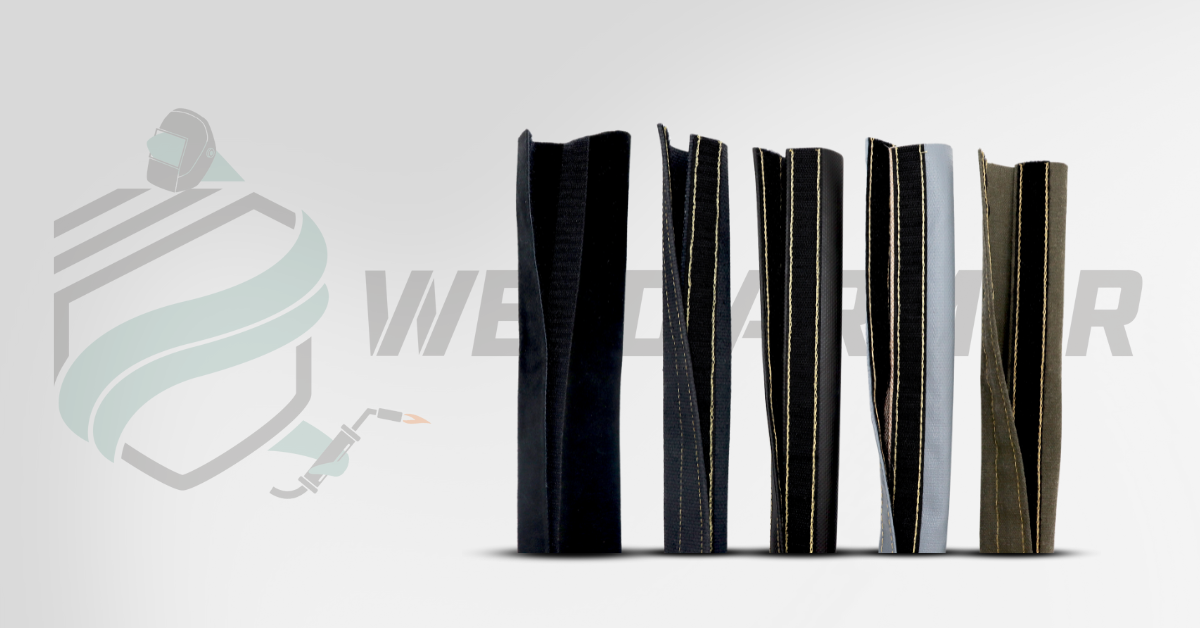

Weld Armor Series Cable Wraps

The Python Weld Armor Series wrap sleeves are the newest additions to the Wrap Sleeve product line, designed to better serve the welding, laser, and robotics community.

The Weld Armor Cable Wrap with multiple material and sizing options offers an ideal solution for your application needs.

With our comprehensive line of five materials - durable leather, versatile neoprene, heat-resistant acrylic, chemically resistant teflon, and cost-effective canvas - there is an ideal wrap for your specific welding process, whether it's MIG, TIG, Arc, laser, plasma cutting, or robotic applications.

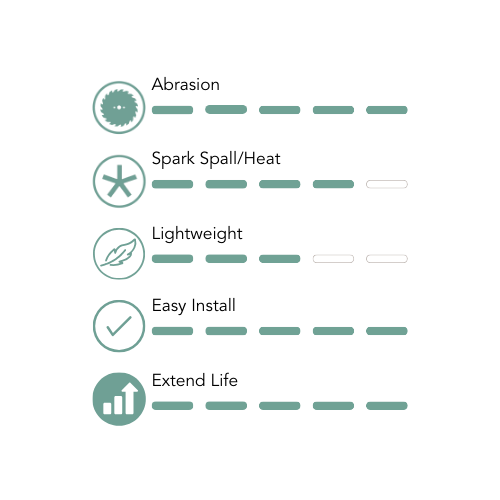

WELD ARMOR FEATURES

• Quick and Easy Installation: Increase productivity

• Secure, Hook-and-Loop Fastener: Welded onto the leather wrap (not sewn) to eliminate loose threads and enhance durability

• Unmatched Protection: Featuring 5 material options

WELD ARMOR BENEFITS

• Extend cable and lead life: Protects your cable from ambient conditions and harsh environments

• Reduce downtime: Quick install and replace the cable wrap sleeves with military grade hook-and-loop technology

• Enhance safety: Protect yourself and others from exposed cables and dangerous electric currents

• Tailored solution: Choose the best material for your application and environment

“The biggest complaint we heard from welding professionals was that sleeves would come apart over time. After digging deeper, we discovered that, regardless of the thread used to sew the the hook-and-loop fasteners, the harsh, abrasive environments would wear down the stitching, causing the hook and loop to detach from the leather wrap. With our new technology, we’ve eliminated sewn stitches entirely by welding the hook and loop directly to the leather wrap. This innovation creates a superior product where the hook and loop remain secure, leaving only the leather material itself subject to wear."

- Mike May, Group Product Manager, Python

Weld Cable Wrap Materials

There are 5 different weld lead wrap materials to choose from, each with unique properties and resistance levels:

Featured: Leather Weld Cable Wrap

Among the five materials, the premium leather wrap provides durability and cutting-edge heat and abrasion resistance, ensuring a longer lifespan for your cable and leads in harsh environments.

It also features welded hook and loop fasteners instead of sewn, solving the #1 issue with leather wraps—stitching failure. Ideal for Arc, MIG, TIG, and laser applications, this leather sleeve is designed to protect your cables and leads, you, and your team.

High Abrasion Resistant Sleeves

Both weld cable wrap sleeves can be used in higher-abrasion environments, checkout the differences between the two options:

| Aspect | Neoprene | Canvas |

|---|---|---|

Sleeve |

|

|

Environment |

Ideal for high-abrasion environments when there is a medium to low amount of spark and spall. |

Ideal in medium abrasion environments where welder leads are suspended and are occasionally dragging on the floor. |

Max Temperature |

250°F |

N/A |

Applications |

|

|

Lifespan |

Up to 6 months |

Up to 4 months |

High Heat Resistant Sleeves

Both weld cable wrap sleeves can be used in high-heat environments, below are the general differences between the materials:

| Aspect | Acrylic | Teflon |

|---|---|---|

Sleeve |

|

|

Environment |

Best for high-heat environments when there is low to no abrasion and lot of spark and spall. |

Ideal when used in application with light to medium grinding, and where a flame is present. |

Max Temperature |

1000°F with continual heat |

600°F |

Applications |

|

|

Lifespan |

Up to 12 months |

Up to 18 months |

Ordering & More Information

Don't let damaged cables disrupt your welding operations. Contact us today to discuss your specific needs and discover the perfect Python Weld Armor solution for your welding environment.