From a distance, it can be easy to get confused when talking about desiccant dryers, believing that all desiccant dryers are virtually the same. Being able to distinguish the difference is paramount in being able to determine which dryer is right for you.

This article will answers those questions and more. Jump to your desired section:

- Regenerative Dryers: Explained

- Desiccant Air Dryers: Explained

- The Difference Between Regenerative and Manual Change

There are several variations of "desiccant" compressed air dryers:

- Heatless regenerated

- Heated regenerated

- Blower Purge

- Desiccant pots (manual change)

The most commonly used of these technologies is heatless regenerative dryers and manual-change desiccant dryers. Both of types of compressed air dryers have desiccant beads within a vessel that serve to dry the air as it passes through the drying media contained within, providing very dry air for your pneumatic application or equipment.

What, then, makes heatless regenerative dryers different from these desiccant pots? Why are regenerative dryers more effective at providing a consistent supply of dry air to your application?

Regenerative dryers: Explained

What is a regenerative dryer?

A regenerative compressed air dryer is an air treatment product that is designed to chemically remove moisture from compressed air. With pre-filters, the dryer becomes even more effective as it will also remove liquid water, oils and particulate.

How Regenerative dryers work:

Desiccant regenerative dryers use multiple canisters of desiccant to remove water vapor from compressed air. As compressed air passes through the desiccant media in one or more of the canisters, water vapor is attracted to the desiccant beads, thereby providing dry compressed air downstream.

What makes the dryer "regenerative" is the timer valve that switches the towers in operation. One tower is actively drying the air while the other is borrowing a small amount of sweep air to purge the media. It's like changing the desiccant canister every two minutes.

Watch the video below for a detailed explanation of how regenerative dryers work.

Desiccant Dryers: explained

What is a desiccant air dryer?

A manual-change desiccant air dryer, or "desiccant pot", is an air treatment product that uses desiccant beads to chemically remove moisture from compressed air. Pre-filters allow dryer to remove liquid water, oils and bulk particulate before entering the desiccant canister.

How desiccant air dryers work:

Desiccant pot style dryers use the same process as regenerative dryers in that the media traps the water vapor molecules as the air passes through, thereby providing dry air downstream. Unfortunately, the media has no way to remove this water vapor so in time, the media will hit a level of saturation where it can no longer remove the water vapor and the media either has to be replaced or it must be removed and regenerated in an oven to “bake” the water vapor molecules out of the desiccant beads.

In short, this is how they work:

- If pre-filters are attached, any liquid water, oils and bulk particulate will be removed before entering the air dryer.

- Once the air enters the dryer, it is directed through a desiccant canister where the media grabs any moisture from the air and adsorbs it onto the beads.

- The dry air exits the dryer, ready for action!

- The canister will need to be manually changed every so often to ensure proper performance of the system.

Typically this technology is cost effective and will effectively remove water moisture if properly maintained.

The Difference Between regenerative dryers and desiccant pots

Alas! We've made it to the best part of the article!

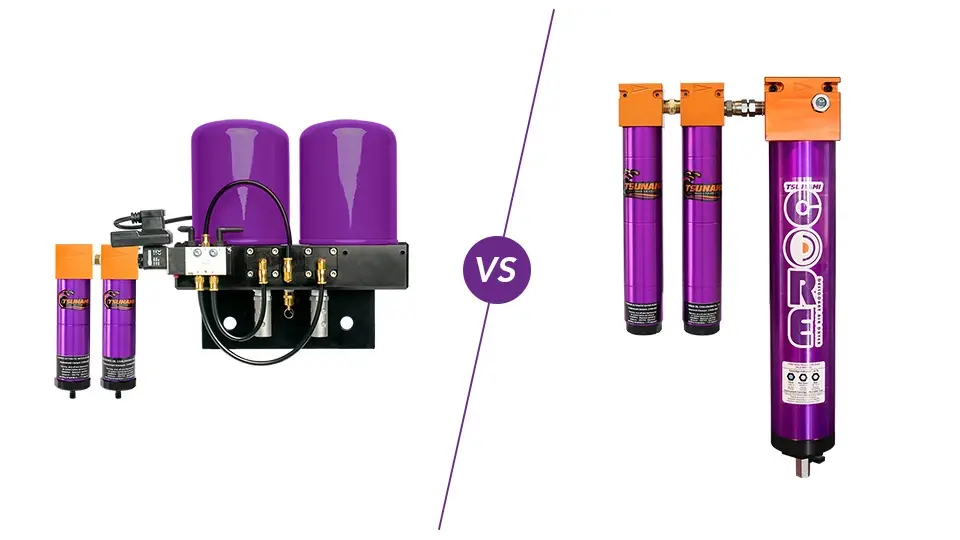

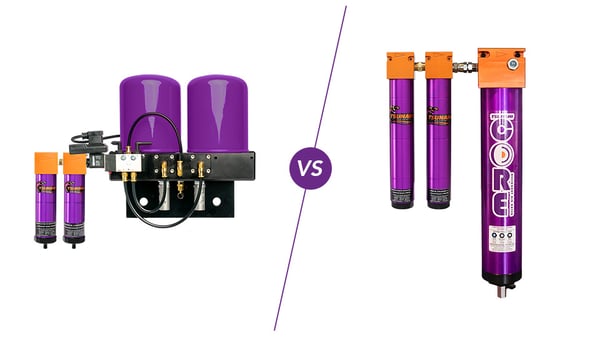

The difference between desiccant pots and a regenerative dryer is:

- Regenerative dryers "regenerate" themselves as they use multiple canisters and a small amount of sweep air to dry the media for repeated use.

- Desiccant posts require the operator to manually change the canisters; ongoing maintenance is required as they become saturated with moisture.

Although it is evident that all desiccant dryers remove water vapor, there are significant differences that can save the user hundreds of dollars annually.

How can a regenerative dryer save you money?

Regenerative dryers save users a considerably amount of time and money in the long run for their compressed air systems.

Why?

Well, compared to desiccant pots that constantly need monitoring and servicing, a regenerative dryer will service itself through the regeneration process and offer consistently dry air; simply replace an oil coalescing element every six months and you will have years of high-quality air. This means less time playing with beads and more uptime for your operation.

What regenerative dryer is right for you? Contact Tsunami Compressed Air Solutions and ask to speak with one of our experts!