Although Tsunami Dryers are simple and robust, following our easy maintenance schedule is recommended for ultimate performance and longevity.

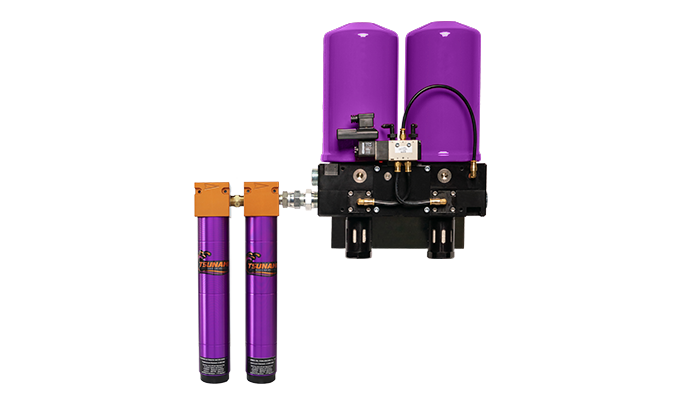

Tsunami Regenerative Dryers are the most simple, robust, and easy to maintain air dryers in the market. When compared to alternative technologies, Tsunami dryers surpass the competition in simplicity, performance, and cost of ownership. Although Tsunami systems are simple and robust, performing routine maintenance is required for ultimate performance and longevity.

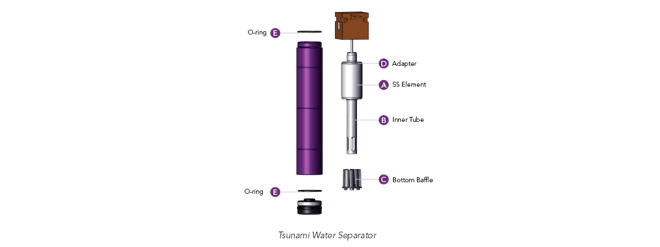

Servicing the Filters: Water Separator

The water separator is constructed with a stainless-steel mesh that removes water and particulates as the air is redirected and coalesced — dropping water and dirt down to the drain. Replacing this element is rarely needed, we recommend only cleaning it when necessary; any sign of servicing can be discovered upon the removal of the outer tube. If the mesh appears dirty/oily and impacted, then the user should unravel the stainless-steel mesh and wash it with warm, soapy water. This is a simple and easy process that will immediately enhance performance and help prevent the drain from fouling. When re-wrapping, be sure the mesh is not too tightly wound as you need it to contact the tube wall.

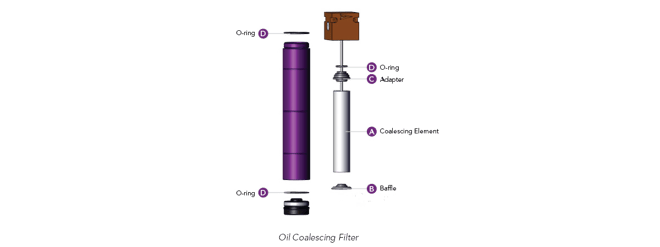

Servicing the Filters: Oil Coalescing Filter

The oil coalescing element is grabbing any remaining oils and fine particulates that are flying through the air system. In most cases this filter saturates quickly and needs to be replaced every 6 months. However, depending on the application, the elements life span may vary. Replacement elements can be purchased individually or in packs of 5. When replacing the element, simply remove the tube, unscrew the bottom baffle, and swap out the filter element.

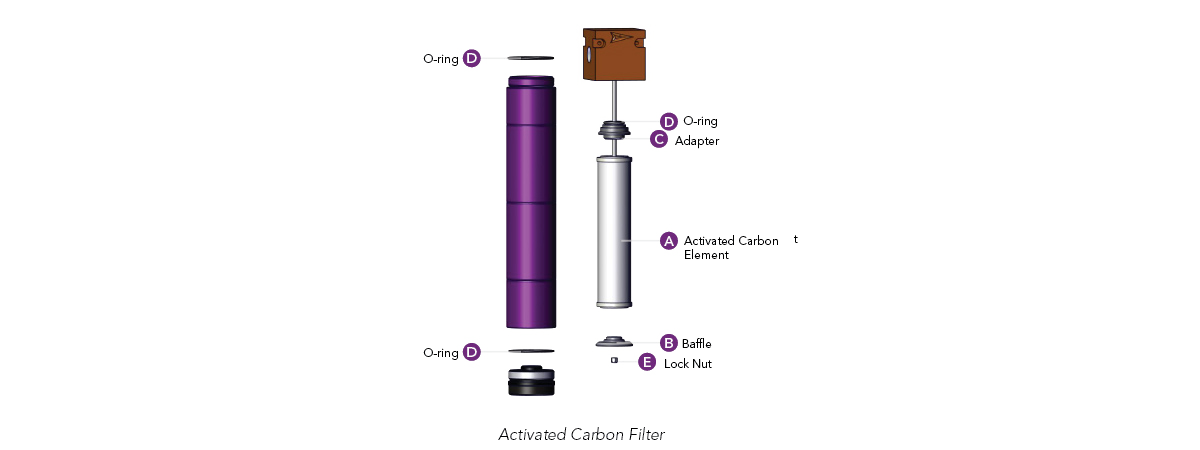

Servicing the Filters: Activated Carbon Filter

The activated carbon filter traps oil vapors as they pass through element. Monitoring this element, and knowing when to replace, is more difficult to measure and usually requires an air test. In most applications, the average life span of the activated carbon element is six (6) months; although some applications may require more frequent element changes. Replacing is as easy as the coalescing element, simply remove the bottom baffle, exchange elements, and reinstall.

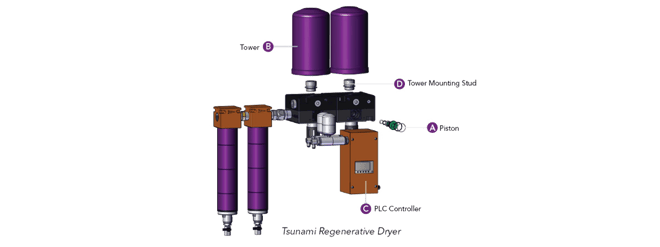

Servicing the Towers

Tsunami’s regenerative air-drying towers are durable and will provide the user with many years of performance; if the pre-filters are serviced regularly. Maintaining the pre-filters keeps liquid water, oils and particulates out of the towers so the desiccant media can effectively adsorb water vapor and humidity efficiently. We recommend changing out the towers every 1-3 years; depending on the application and pre-filter maintenance.

Greasing the Pistons

When servicing the pre-filters, take a few minutes to grease the pistons as well. Using a hex wrench, loosen the front bolts and remove the piston caps. Pull out the pistons, use a ½”-13 bolt if needed, and apply a thin film of grease to the piston seals, spring, and dryer bore.

Questions? Contact Tsunami Compressed Air Solutions and ask to speak with one of our experts