2 min read

Paint Bubbles? You Might Need a Better Air Filter

Tsunami Team

:

Apr 25, 2022 12:00:00 AM

Paint bubbles are one thing auto body shops can do without.

Air filters are an important investment to help address this issue. Other potential issues are dieback and fisheye, which are present as a reduction of the gloss and occurs when auto body shops are located in a high humidity/dirty environment. Repairing paint blemishes can be expensive, making prevention the better, more cost-effective alternative.

A regenerative desiccant dryer has multiple facets in any auto body shop. Not only are they designed to provide consistent ultra-low humidity, they also reduce the contaminants in the air that would decrease the quality in any painting applications.

Typically, painting applications require less than 10% humidity but aim for below 5%.

A regenerative desiccant air dryer is a long-term solution to these problems.

Once the installation is complete, the machine has a lifetime expectancy. However, it is important to pay attention to the signs and recognize when certain parts need to be replaced.

How Air Filters and Dryers Reduce Painting Defect Caused by Air Contaminants in Compressed Air Systems

While high humidity is an issue that auto body shops deal with on a regular basis, it is not the only potential environmental factor that interferes with a quality paint job.

Dust, oils and other airborne contaminates are also pulled in to the air stream from the compressor. Choosing an air treatment solution that removes this debris is crucial to the success of an auto body shop.

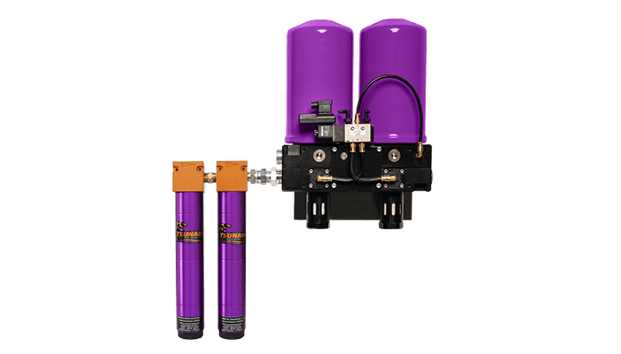

Tsunami Compressed Air Systems offers two different systems of air dryers to help with these issues. Both the Pure Series and Ultra Series systems provide dry compressed air that is cleaned of contaminants.

Pure Series – Build for Performance and Ease of Use

- Available as a wall mounted or tank-mounted option

- Offers two-stage Tsunami pre-filtration process (water separator & oil coalescing filter)

- Dual tower with automatic drains

Ultra Series – Bigger and More Flexible

- Offers a more efficient system with a Programmable Logic Controller

- Comes with Moisture Minder pneumatic drains

- Factory expandable – filters are oversized to allow for additional dryer towers to be added if a shop/facility expanded its air requirements

- Rail-mounted option available

Benefits of Filtering Compressed Air Systems: Painting and Beyond

When you choose to incorporate a Tsunami desiccant regenerative air dryer into your workshop setup, the benefit is made clear quickly.

The machine has a lifetime expectancy. However, it is important to pay attention to the signs and recognize when certain parts need to be replaced.

The twin-desiccant towers, for example, need to be replaced every three to five years. The oil coalescing filter element needs to be replaced every six months.

High quality and durability in your air filters and dryers are a necessity, as these characteristics assure you that the cleanest air is being used in the booth – air that is both oil and dirt-free.

The corrosion of filter heads has been a cause of fish eye, so filters that are treated and protected from corrosion are also important.

How to Choose the Best Compressed Air Filtration System | Consult the Experts

We have established why a compressed air desiccant dryer is a necessary addition to your shop equipment. However, we also need to talk about who to rely on for the system you can trust.

Tsunami Compressed Air Solutions has spent years fine-tuning their air filtration systems. This provides you with the reliable, robust system you need to successfully avoid paint bubbles and other defects.

Tsunami also is available to help create a custom solution that improves your profit and cuts down on time spent fixing defects.

Contact Tsunami Compressed Air Solutions to discuss the right air treatment for your shop.

-1.png?width=482&height=482&name=SuburbanManufacturing_Tsunami_PURE5_NoStand%20(web)-1.png)