.jpg)

THE CHOSEN COMPRESSED AIR SOLUTION FOR AUTOMOTIVE APPLICATIONS

CLEAN DRY AIR FOR THE PROFESSIONAL BODY SHOP

Compressed air that contains dirt, water, and other contaminants is destructive to professional paint jobs and pro finishing. Using contaminated air in a particular application causes poor results instead of the high-quality finishes that painters, and the auto body industry, have come to expect. Taking the necessary steps to provide ultimate clean, dry air eliminates the risk of producing a poor paint job for high-paying customers.

AUTO PAINTING ISSUES

Do any of these problems in your paint seem familiar?

- Low gloss

- Hazing

- Cratering

- Dye back

- Fish eye

Over half of all paint finish issues can be attributed to the quality of your compressed air!

THE TSUNAMI SOLUTION

When you upgrade to a Tsunami, you take the guesswork out of compressed air.

- Remove humidity

- Eliminate contaminates

- Get rid of oils, oil vapor

- Filtration & drying products

- Consistent results

Our innovative technology provides ultra-dry air for spraying today's complex waterborne paints.

REGENERATIVE AIR DRYERS FOR PAINT,

BODY, & EQUIPMENT NEEDS.

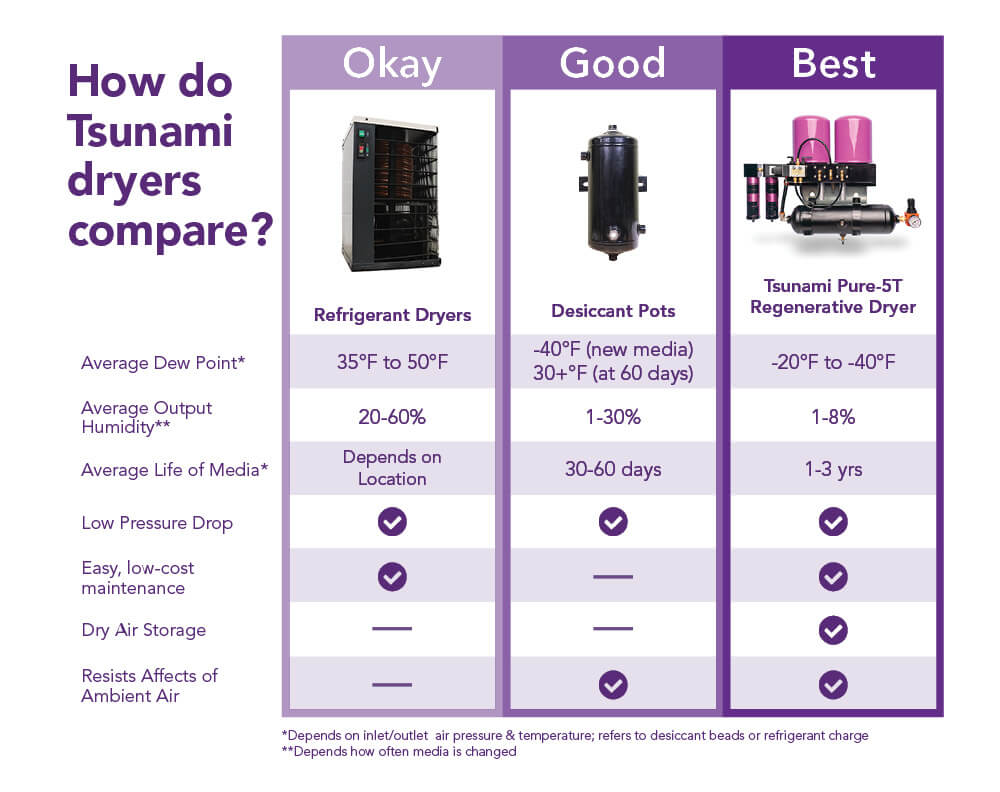

Comparative technologies like desiccant pots and refrigerant dryers show promising results but fail when faced with large surges of air and/or longer operating times. In desiccant pots, the media will reach a point of saturation where it can no longer remove the water vapor and the beads must be replaced. Refrigerant dryers fail when large surges of air pull the air too quickly through the system, not allowing the coolant to cool the air down to its dew point.

Tsunami regenerative dryers use multiple canisters of desiccant that regenerate using sweep air. This means clean, dry air for any environment or application.

HOW DO TSUNAMI DRYERS COMPARE TO ALTERNATIVE DRYING SOLUTIONS?

- Consistently lower average dew point

- Lower average humidity output

- Longer life of drying media

- Easy, low-cost maintenance