Air Treatment for Spray Foam Rigs

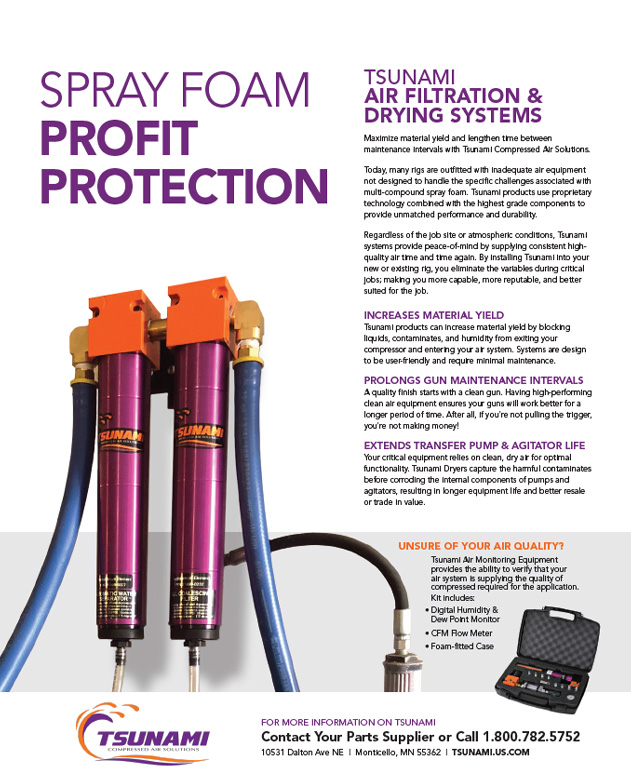

THE TSUNAMI SPRAY FOAM PROFIT PROTECTION Solutions

HOW CAN CLEAN DRY AIR REDUCE SPRAY FOAM DOWNTIME?

Tsunami Filters and Dryers add cash to your business by providing less downtime. Clean, dry air prevents frozen air lines, contaminated pumps, and damaged spray guns.

Tsunami products use proprietary technology combined with the highest grade components to provide unmatched performance and durability. Regardless of the job site or atmospheric conditions, Tsunami systems will give you peace-of-mind time and time again.

INCREASE MATERIAL YIELD

Tsunami products will increase material yield by blocking liquids, contaminants, and humidity from entering your air system from the compressor.

PROLONG MAINTENANCE INTERVALS

A quality finish starts with a clean gun. Having high-performing clean air equipment will get you there.

EXTEND EQUIPMENT LIFE

Tsunami Dryers capture the harmful contaminants and moisture before corroding the internal components of pumps and agitators.

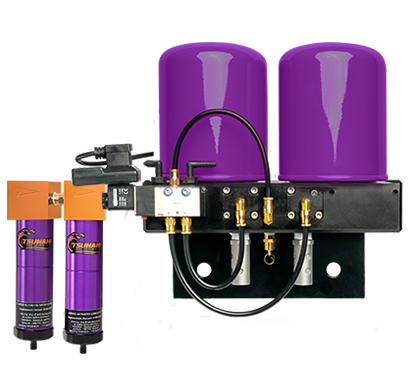

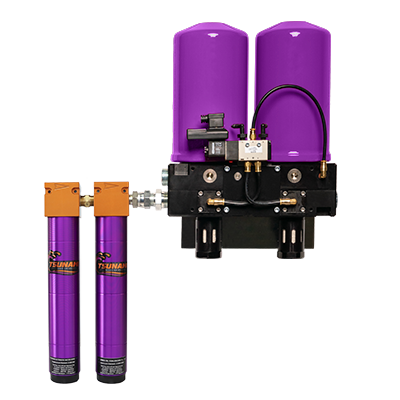

Air compressor Filtration & Drying Systems

WHICH AIR DRYER DO YOU NEED?

Our experts recommend the following:

|

DRYER |

ITEM # |

MAX FLOW |

COMPRESSOR RATING |

| Pure-5 | 21999-1105 | 15 CFM | 5hp |

| Pure-7 | 21999-1140 | 25 CFM | 7.5hp |

| Pure-10 | 21999-1010 | 40 CFM | 10hp |

| Pure-20 | 21999-1020 | 80 CFM | 20hp |

Aftercooler for Air Compressors

The versatile, wall-mount aftercooler delivers air cooling to spray foam applications sensitive to moisture contamination. By installing an aftercooler on the back end of your air compressor, you can significantly reduce the moisture load entering downstream dryers, optimize dryer performance, extend equipment life, and minimize costly downtime.

Respiratory Protection for Spray Foam

When you need Grade D breathing air in your facilities and job sites, breathing air panels are the optimal solution. The complete system includes a 3-stage filtration system that effectively removes harmful particles, moisture, and other contaminants before entering your airways, a carbon monoxide alarm, and a CO monitor calibrator with Autocal®.

Regenerative Dryer

Tsunami's PURE Dryer provides clean, dry at the point-of-use. Our PURE line is simple, easy to install and will remove liquid water, oils, particulate AND remaining humidity found in the air line.

Our air dryers guarantee to enhance your operations, final product, and shop efficiency when installed to where it's needed most.

2-Stage Filter

All 2-stage filter packages feature a water separator, oil coalescing filter, and mounting bracket; some available with air regulators. These packages enhance the cleanliness of your air by pulling out water, oils, and pesky contaminants.

Tsunami Filter Packages are available from 20 CFM to 120 CFM to meet your air demand.

Breathing Air

Tsunami Breathing Air is essential for the health and safety everyone working in the shop. Whether wood shavings are flying or finishing spray is being applied, having clean air is vital for respiratory health in these conditions.

Meeting OSHA Grade D breathing air requirements with the help of a Breathing Air System means you can rest assured each breath is safe in the work environment.

Selecting the proper air treatment products for your shop is essential in avoiding the pitfalls of bad air. Many cheap filters and dryers do not effectively remove all the contaminants and may require constant servicing or replacement.

With Tsunami, you can expect the clean, dry air your shop needs to run effectively AND enjoy minimal servicing with years of performance.

Why should you choose Tsunami over competing brands? Tsunami is:

higher quality, longer lasting

Experience a higher quality product that cleans that air and lasts longer than cheaper filters.

hassle-free servicing

Built to service quickly and efficiently to increase productivity and decrease downtime.

versatile

Products are easy to mount, install, & operate so you can place them where your operations require improvements.