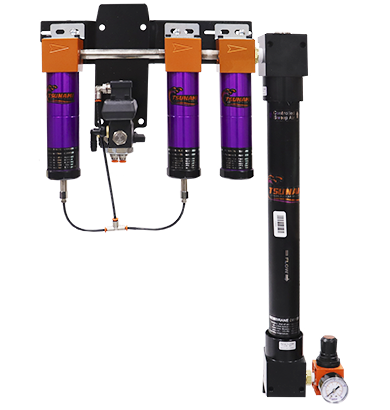

Tsunami Membrane Dryers

15 CFM / 20 CFM 3-Stage Membrane Air Dryers

3-Stage Pre-Filtration

The 3-Stage Membrane Dryer includes a water separator, oil coalescing filter, activated carbon filter and membrane dryer. Incoming air enters the filters where liquid water, oils, aerosols and particulates are removed. Then, the air enters the Membrane Dryer where water vapor is removed from the air.

15 CFM

20 CFM

Features:

-

3-stage Pre-filtration; Water Separator, Oil Coalescing Filter and Activated Carbon Filter

-

Membrane Dryer Core

-

Automatic Drains

-

Wall Mounting Brackets

-

Outlet Regulator

-

Heater pads available for cold temp applications

-

Optional: C1D1 Compatible for hazardous locations

Benefits:

Dryer Performance:

-

Low relative humidity - down to .01% RH

-

Dew points down to -80°F

-

Easy, low-cost maintenance; under $100/year average

Filter Performance:

1st Stage Water Separator:

-

Removes liquid water

-

Filters particulate down to 10 micron

2nd Stage Oil Coalescing Filter:

-

Removes bulk oils and aerosols

-

Filters particulate down to .01 micron

3rd Stage Activated Carbon Filter:

-

Removes oil vapors down to .003 ppm

Min/Max Air Inlet Temperature: 100°F

Min/Max Operating Pressure: 175

Power Requirement: 120V

Filter Package for 15 CFM Unit: #21999-0421

Filter Package for 20 CFM Unit: #21999-0255

Sizing & Ordering Information

MAX CFM: 15

ITEM #: 21999-0957

NPT: ¼"

DRAIN: Electronic

MAX PSI: 175

MAX TEMP: 100°F

WEIGHT: 12 lbs

DIMENSIONS: 24½" x 18½" x 5½"

MAX CFM: 20

ITEM #: 21999-0524

NPT: ½"

DRAIN: Electronic

MAX PSI: 175

MAX TEMP: 100°F

WEIGHT: 22 lbs

DIMENSIONS: 23" x 23½" x 5½"

| MAX CFM | ITEM # | PORT SIZE (NPT) | DRAIN | MAX PSI | MAX°F | WEIGHT (LBS) | DIMENSIONS (IN) | MSRP |

|---|---|---|---|---|---|---|---|---|

15 |

21999-0957 |

¼" |

Electronic |

175 |

100 |

12 |

24½" x 18½" x 5½" |

$2,151.00 |

20 |

21999-0524 |

½" |

Electronic |

175 |

100 |

22 |

23" x 23½" x 5½" |

$2,543.00 |

Product Videos

2 min read

Tsunami Aftercooler - New Product Winter 2025

Mar 3, 2025 by Tsunami Team

3 min read

Benefits of Point-Of-Use For Compressed Air Dryers

Jan 20, 2025 by Tsunami Team