Compressed Air Dryer

Regenerative Desiccant

Tsunami Pure-1 Series

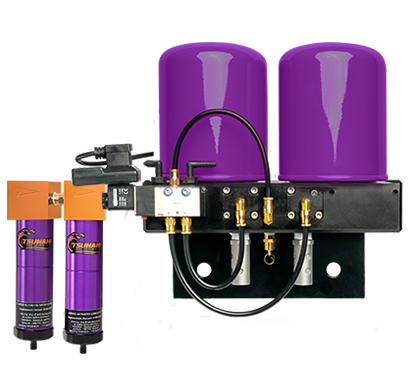

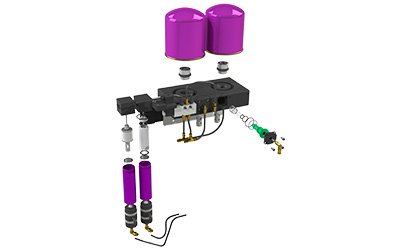

The Pure-1 Series Regenerative Dryer is rated for 5 CFM airflow, and fitted for 1 Hp compressors. The Pure-1 system uses a Solenoid Timer Valve to control the dryer and Tsunami pre-filtration to assure removal of water, oil, and particulates before entering the dryer.

Tsunami Pre Filtration

Tsunami pre-filtration includes the water separator and oil coalescing filter to remove liquid water, bulk oils and particulate.

Regenerative Towers

Tsunami’s Regenerative Drying Technology uses sweep air to regenerate the towers during operation. It's like changing the desiccant every two minutes.

Efficient Construction

Pure Series Dryers are efficiently designed and constructed with very few moving parts, reducing potential stress points.

Features:

-

2-stage Pre-filtration; Water Separator, Oil Coalescing Filter

-

Molecular Sieve Desiccant

-

Solenoid Valve Timer

-

Automatic Drains

-

Purge Exhaust Mufflers

-

Wall Mounting Brackets

-

Optional: C1D1 compatible for hazardous locations

-

Heater pads available for cold temp applications

Benefits:

Dryer Performance:

-

Low relative humidity - down to .01% RH

-

Dew points down to -80°F

-

Easy, low-cost maintenance; under $100/year average

Filter Performance:

1st Stage Water Separator:

-

Removes liquid water

-

Filters particulate down to 10 micron

2nd Stage Oil Coalescing Filter:

-

Removes bulk oils and aerosols

-

Filters particulate down to .01 micron

Max Air Inlet Temperature: 150°F

Min/Max Operating Pressure: 80/175

Power Requirement: 120V

Compressor Size: 1 Hp

Water Separator: #21999-0390

-

Replacement Element: #21999-0390-Z-FD

Oil Coalescing Filter: #21999-0390-Z-FD

-

Replacement Element: #21999-0394

Air Consumption Averages and Cycle Time

| ITEM # | # of Towers | Orifice | CFM Consumption | Cycle Time | Tower Drying Time | # of Towers Drying | # of Towers Regenerating |

|---|---|---|---|---|---|---|---|

21999-1134 |

2 |

.012" |

.3 |

2 min |

120 sec |

1 |

1 |

21999-1134-MM |

2 |

.012" |

.3 |

2 min |

120 sec |

1 |

1 |

*Dryer flow rates based on 100°F at 175 PSI an outlet pressure of 100 PSI. (Minimum inlet pressure 80 PSI Lower inlet pressure and higher temperatures affect the performance and quality of the downstream air)

Sizing & Ordering Information

-1.png?width=500&height=500&name=SuburbanManufacturing_Tsunami_PURE5_NoStand%20(web)-1.png)

CFM: 5

ITEM #: 21999-1134

DRAIN: Float

NPT: ¼" INLET / ½" OUTLET

MAX PSI: 175

MAX TEMP: 150°F

WEIGHT: 42 lbs

DIMENSIONS: 15" x 22" x 8"

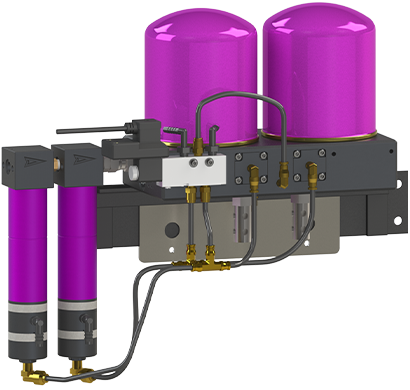

Tsunami Pure-1 Series Regenerative Dryer with Pneumatic Drains

CFM: 5

ITEM #: 21999-1134-MM

DRAIN: Pneumatic

NPT: ¼" INLET / ½" OUTLET

MAX PSI: 175

MAX TEMP: 150°F

WEIGHT: 42 lbs

DIMENSIONS: 18" x 22" x 8"

| MAX CFM | ITEM # | DRAIN | NPT | MAX PSI | MAX °F | WEIGHT | DIMENSIONS (IN) | MSRP |

|---|---|---|---|---|---|---|---|---|

5 |

21999-1134 |

Float |

¼" INLET / ½" OUTLET |

175 |

150 |

42 lbs |

15 x 22 x 8 |

$1,931.00 |

5 |

21999-1134-MM |

Pneumatic |

¼" INLET / ½" OUTLET |

175 |

150 |

42 lbs |

18 x 22 x 8 |

$2,201.00 |

Product Videos

3 min read

Benefits of Point-Of-Use For Compressed Air Dryers

Jan 20, 2025 by Tsunami Team

4 min read

The Importance of Humidity Control with Regenerative Dryers in Industrial Applications

Dec 4, 2024 by Tsunami Team