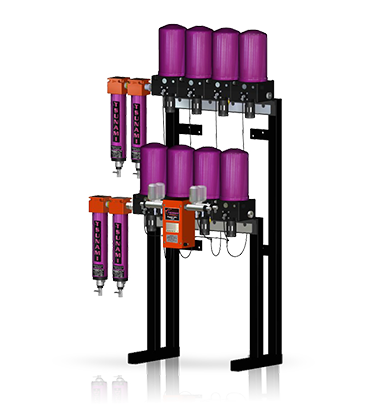

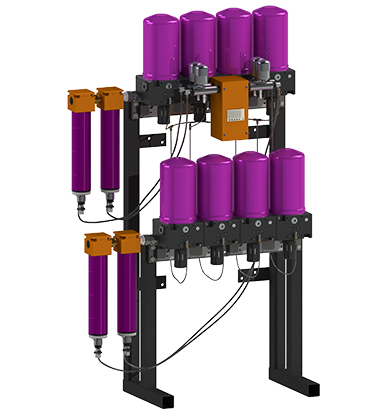

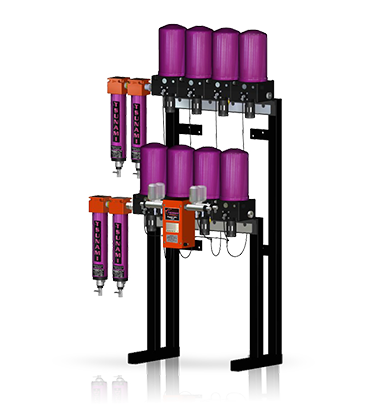

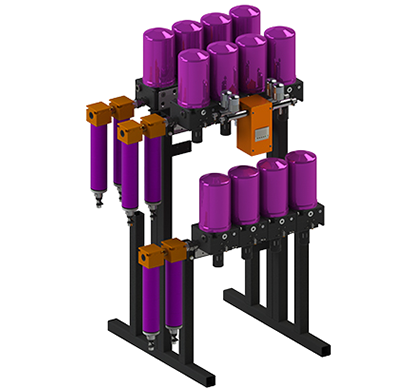

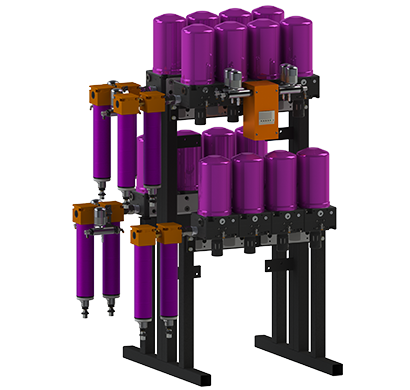

Tsunami Ultra Series

160-400 CFM Rail Mounted Compressed Air Dryers

Regenerative Desiccant

Tsunami Rail Mounted Regenerative Dryers are built to withstand the largest surges of contamination. Similar to other Tsunami drying systems, these dual-inlet units are built as complete packages. Choose from 160 - 400 CFM units or build your own.

Tsunami Pre Filtration

Tsunami pre-filtration includes the water separator and oil coalescing filter to remove liquid water, bulk oils and particulate.

PLC Controller

The Programmable Logic Controller cycles the dryers and pneumatic drains - optimizing efficiency and allowing for dryer expansion.

Factory Expandable

Ultra Series Dryers are factory expandable. Increase the dryer capacity as your business's air demands increase.

Features:

-

2-stage Pre-filtration; Water Separator, Oil Coalescing Filter

-

Molecular Sieve Desiccant

-

Programmable Logic Controller

-

Automatic Pneumatic Drains

-

Purge Exhaust Mufflers

-

Auxiliary port allows for filtered but not dried air downstream

-

Heater pads available for cold temp applications

-

Optional: C1D1 Compatible for hazardous locations

Benefits:

Dryer Performance:

-

Low relative humidity - down to .01% RH

-

Dew points down to -80°F

-

Easy, low-cost maintenance; under $100/year average

Filter Performance:

1st Stage Water Separator:

-

Removes liquid water

-

Filters particulate down to 10 micron

2nd Stage Oil Coalescing Filter:

-

Removes bulk oils and aerosols

-

Filters particulate down to .01 micron

Min/Max Air Inlet Temperature: 150°F

Min/Max Operating Pressure: 175

Power Requirement: 120V

Fitted for 40, 50, 75 or 100 Hp Compressors.

Water Separator Replacement Element: #21999-0228

Oil Coalescing Filter Replacement Element: #21999-0202-Z-SP

Air Consumption Averages and Cycle Time

| ITEM # | # of Towers | Orifice | CFM Consumption | Cycle Time | Tower Drying Time | # of Towers Drying | # of Towers Regenerating |

|---|---|---|---|---|---|---|---|

21999-0740 |

8 |

.045" |

8 |

45 sec |

135 sec |

6 |

2 |

21999-0750 |

8 |

.060" |

16 |

45 sec |

135 sec |

6 |

2 |

21999-0755 |

12 |

.060" |

24 |

45 sec |

135 sec |

9 |

3 |

21999-0760 |

16 |

.060" |

32 |

45 sec |

135 sec |

12 |

4 |

*Dryer flow rates based on 100°F at 175 PSI an outlet pressure of 100 PSI. (Minimum inlet pressure 80 PSI Lower inlet pressure and higher temperatures affect the performance and quality of the downstream air)

Sizing & Ordering Information

CFM: 160

ITEM #: 21999-0740

NPT: 1"

DRAIN: PNEUMATIC

MAX PSI 175

MAX TEMP: 150°F

WEIGHT: 267 lbs

DIMENSIONS: 66" x 31" x 21"

CFM: 200

ITEM #: 21999-0750

NPT: 1"

DRAIN: PNEUMATIC

MAX PSI 175

MAX TEMP: 150°F

WEIGHT: 267 lbs

DIMENSIONS: 66" x 36" x 21"

CFM: 300

ITEM #: 21999-0755

NPT: 1"

DRAIN: PNEUMATIC

MAX PSI 175

MAX TEMP: 150°F

WEIGHT: 428 lbs

DIMENSIONS: 66" x 36" x 42"

CFM: 400

ITEM #: 21999-0760

NPT: 1"

DRAIN: PNEUMATIC

MAX PSI 175

MAX TEMP: 150°F

WEIGHT: 534 lbs

DIMENSIONS: 66" x 36" x 42"

| MAX CFM | ITEM # | PORT SIZE (NPT) | DRAIN | MAX PSI | MAX °F | WEIGHT (LBS) | DIMENSIONS (IN) | MSRP |

|---|---|---|---|---|---|---|---|---|

160 |

21999-0740 |

1" |

Pneumatic |

175 |

150 |

267 |

66" x 31" x 21" |

$15,531.00 |

200 |

21999-0750 |

1" |

Pneumatic |

175 |

150 |

267 |

66" x 36" x 21" |

$15,531.00 |

300 |

21999-0755 |

1" |

Pneumatic |

175 |

150 |

428 |

66" x 36" x 42" |

$21,634.00 |

400 |

21999-0760 |

1" |

Pneumatic |

175 |

150 |

538 |

66" x 36" x 42" |

$29,137.00 |

Product Videos

3 min read

Cycling vs Non-Cycling Refrigerated Air Dryers: What's the Difference?

Tsunami Team: Nov 7, 2025

4 min read

Understanding C1D1 Hazardous Environment Requirements and Meeting Them

Tsunami Team: Sep 3, 2025

© 2025 Suburban Manufacturing