2 min read

How It Works: Oil Coalescing and Carbon Filters for Compressed Air

Tsunami Team

:

Jan 30, 2024 10:37:35 AM

When it comes to compressed air applications, the filters you put on them are extremely important. Two often overlooked options are oil coalescing filters and activated carbon filters. These filters are beneficial in a variety of applications, and aid in giving you the cleanest air possible. Let's talk more about what they do.

In this article, we'll discuss how oil coalescing and carbon filters work:

- What oil coalescing filters and activated carbon filters do

- How oil coalescing filters and activated carbon filters work

- Benefits of adding filters to an application

- How to pick the filters you need

What OIL COALESCING and Activated Carbon Filters do

Both oil coalescing and activated carbon filters offer advantages to your air systems. There are a variety of particulates unseen by the human eye that can sneak their way into your system and wreak havoc on your equipment. A way to avoid system issues? Having filters to pull out the gunk before it can touch your pristine machines, tools, and other applications. Both aid in keeping pesky contaminants out.

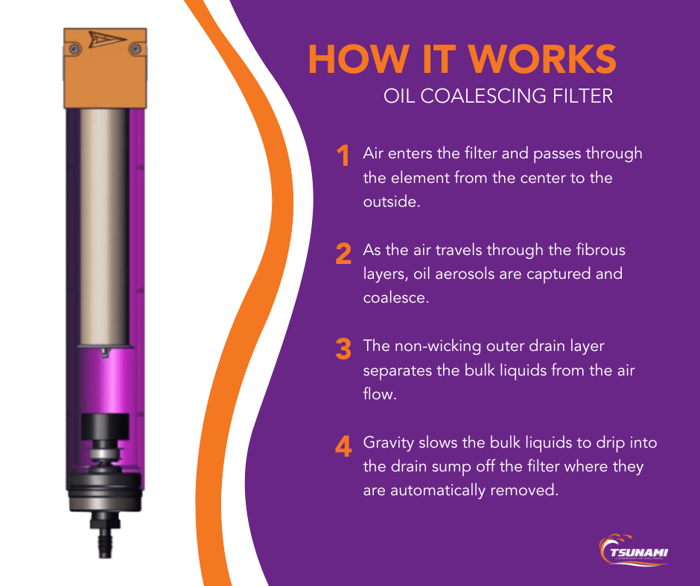

- Oil coalescing filters: designed to remove oils, oil aerosols, and fine particulates out of the air.

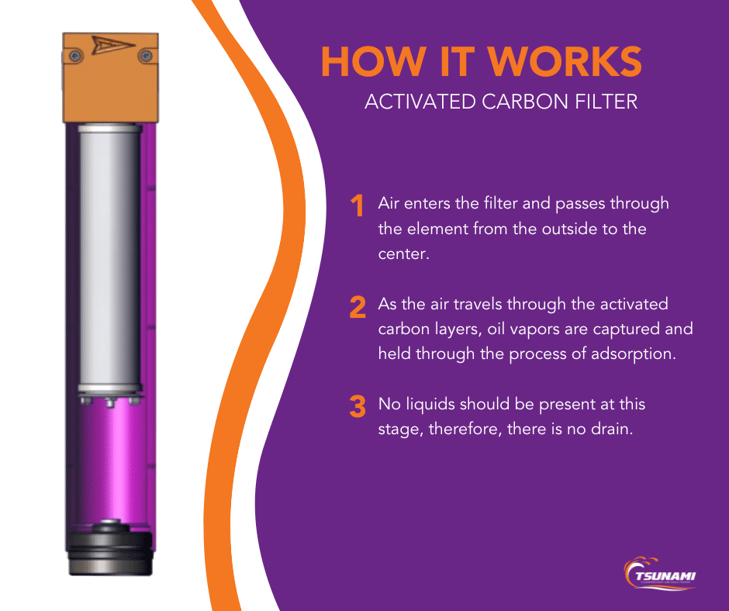

- Activated carbon filters: designed to remove oil vapors, odor, and taste from the air. These are the undetectable, but oftentimes crucial contaminants that need to be removed from the air stream; especially for applications in the food and pharmaceutical industries.

How are these contaminants removed and how do these filters work? Let's get into it.

How OIL COALESCING and Activated Carbon Filters Work

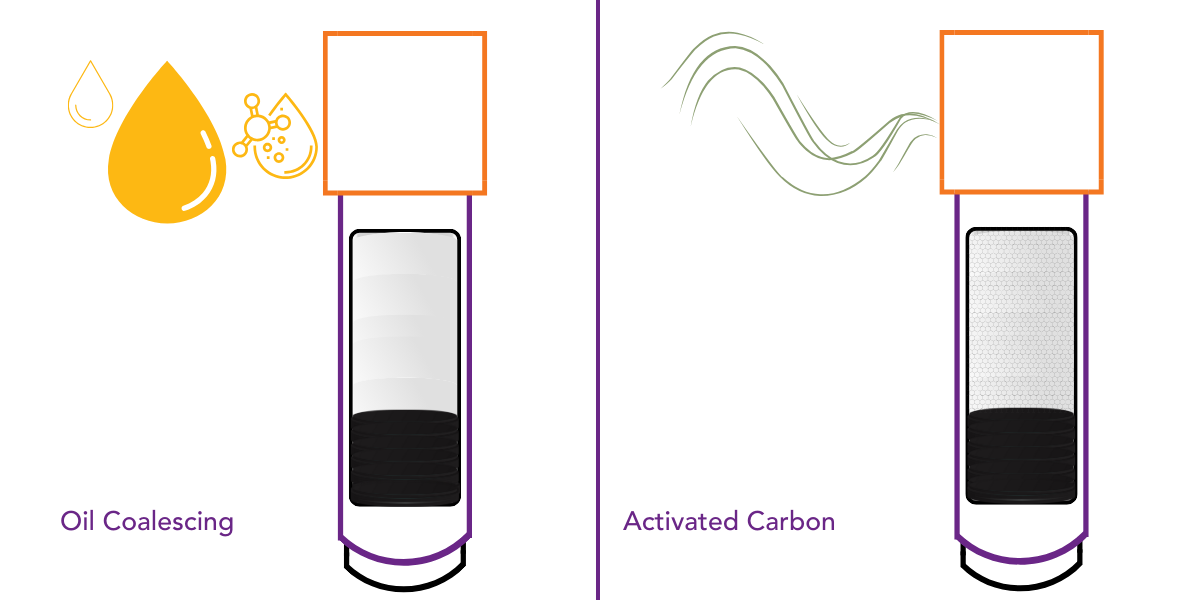

Both of these air filters have similar, but distinct processes to remove their respective contaminants from the air stream before it enters your equipment. Here's how they work:

Oil Coalescing Filter

Activated Carbon Filter

Benefits of Adding Filters to an Application

As you can see, oil coalescing and activated carbon filters function a bit differently than the other; but when working together, they create very clean, odorless air. There are quite a few benefits of adding these filters to your air system:

- No rust. With the help of the oil coalescing filter (in combination with a water separator) there is a slim chance any water will sneak into your equipment. Oil coalescing filters catch those fine particulates and aerosols that can still make their way through a water separator.

- Equipment damage? When installed properly, activated carbon filters and oil coalescing filters offer unmatched protection to your equipment. This means catching sneaky contaminants that can degrade equipment performance over time.

- A clean application every time. Both of these filters catch oils and vapors that are responsible for ruining a clean application. No more splotches, streaks, or uneven applications.

- Gunk-free machines. By having these filters attached to your system, they collect oils from the air - which means tools and machines will run smoothly with no contaminant build up over time.

- Low maintenance. The oil coalescing filter and activated carbon filter need to be replaced every 6 months with a quick element replacement; in extreme circumstances, replace every 3 months.

- Decreased downtime, increased profit. With quick maintenance that keeps machines running, tools running, and applications looking good - these filters provide significant benefits in the long run. We call that a win-win.

How to pick the filters you need

When it comes to a compressed air system, having the filters you need to maximize efficiency is a must to get exceptional results. There are a few filter combinations that may be right for your system between a water separator, oil coalescing filter, and activated carbon filter. Don't know where to start? Tsunami has you covered. Our experts are ready to help you find the filters you need for your compressed air system. Contact a compressed air professional to learn more about all of our filter options, and what you need based on your equipment's specifications.